1. Maintenance of gas engines

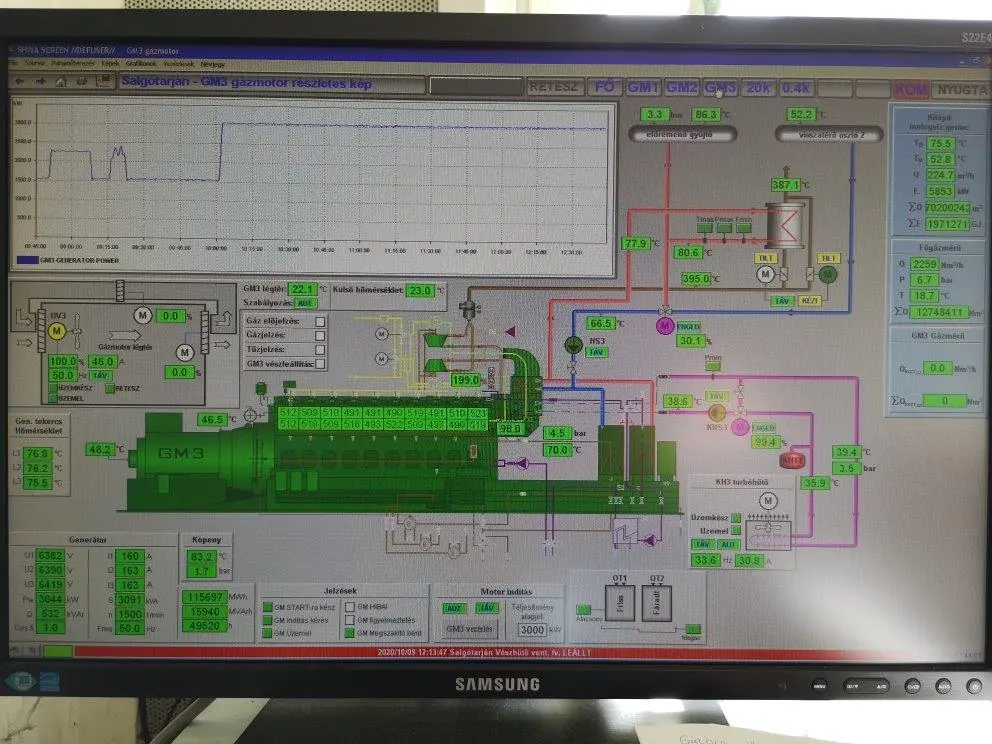

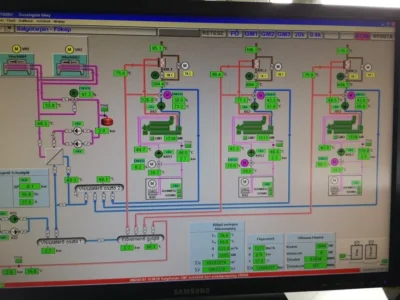

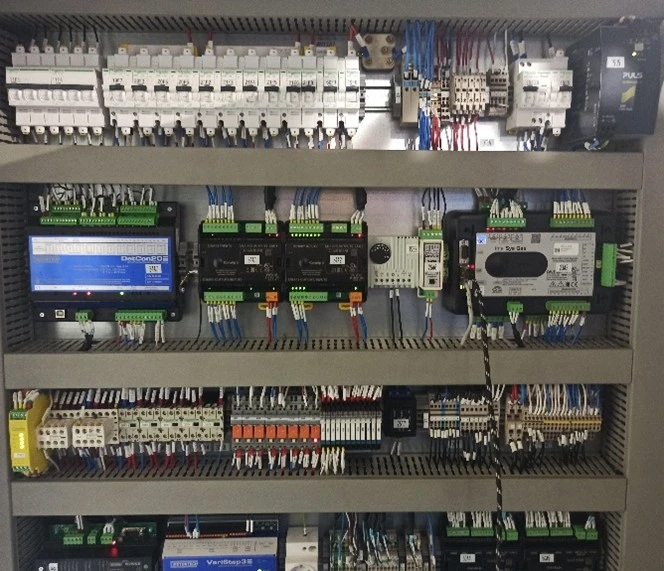

Maintenance of gas engines was done on the basis of the manufacturer’s procedure, including the complete auxiliary systems such as: heat exchangers, turbo cooling pumps, modular cooling pumps, etc.

Engine No.1 and No.3 with generators were completely dismantled and removed from engine rooms.

Genset number two was completely disassembled in the engine room. The jobs that were involved in this renewal of the machine are: changing the bearings of the main shaft, replacing/overhauling the pistons and connecting rods, machining and overhauling of the cylinder heads and liners, crankshaft inspection, generator maintenance etc.

Basically complete engine and auxiliary systems were dismantled, cleaned, inspected, repaired and/or replaced.

The auxiliary systems also included the repair of the complete exhaust system with the exhaust heat exchanger.